Fundamentals of modern manufacturing materials processes and systems 7th edition – Embark on a comprehensive exploration of the transformative world of modern manufacturing with “Fundamentals of Modern Manufacturing Materials Processes and Systems, 7th Edition.” This authoritative guide delves into the evolution, significance, and impact of advanced materials and manufacturing techniques, shaping the future of various industries.

From the properties and applications of composites, ceramics, and polymers to the intricacies of casting, forming, and machining processes, this edition unravels the complexities of modern manufacturing. It emphasizes the critical role of quality control and inspection techniques, ensuring product excellence.

Furthermore, it sheds light on sustainability and environmental considerations, highlighting responsible manufacturing practices that minimize waste and emissions.

Introduction to Modern Manufacturing Materials Processes and Systems

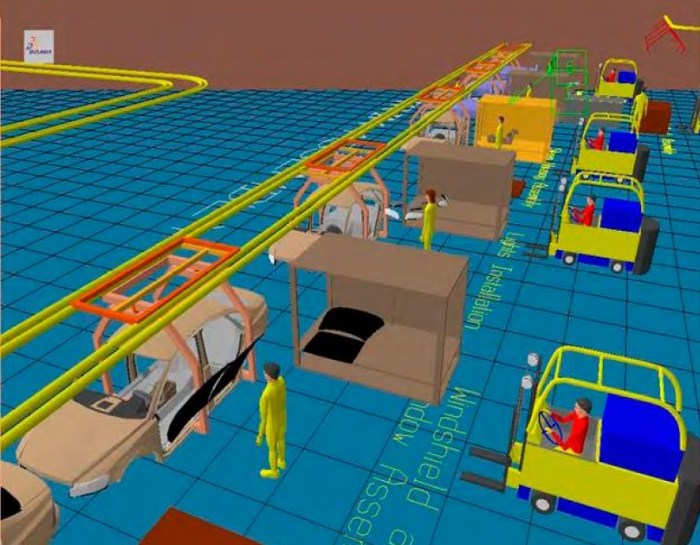

Modern manufacturing materials processes and systems have evolved significantly, revolutionizing various industries. These advancements have enabled the production of high-performance materials with enhanced properties, leading to innovative applications and improved product quality.

The impact of these advancements extends across sectors such as aerospace, automotive, healthcare, and electronics. They have facilitated the development of lightweight, durable materials for aircraft, fuel-efficient engines for vehicles, biocompatible implants for medical devices, and advanced semiconductors for electronic systems.

Properties and Applications of Advanced Materials

Advanced materials possess unique properties that make them suitable for specific applications. Composites, for instance, combine different materials to achieve tailored properties, such as high strength-to-weight ratio, corrosion resistance, and electrical conductivity.

Ceramics offer exceptional hardness, thermal stability, and wear resistance, making them ideal for cutting tools, aerospace components, and medical implants. Polymers, on the other hand, provide flexibility, low weight, and electrical insulation, finding applications in packaging, automotive parts, and electronics.

Advantages and Limitations

- Composites: High strength-to-weight ratio, but can be expensive and complex to manufacture.

- Ceramics: Excellent hardness and thermal stability, but brittle and susceptible to fracture.

- Polymers: Flexible and lightweight, but can have limited strength and temperature resistance.

Manufacturing Processes for Advanced Materials

The manufacturing processes for advanced materials vary depending on the material properties and desired applications. Casting involves pouring molten material into a mold to create a desired shape. Forming processes, such as rolling, forging, and extrusion, shape materials by applying mechanical force.

Machining processes, including turning, milling, and grinding, remove material to achieve precise dimensions and surface finishes.

Principles, Advantages, and Limitations, Fundamentals of modern manufacturing materials processes and systems 7th edition

- Casting: Produces complex shapes, but can have porosity and shrinkage issues.

- Forming: Provides high strength and dimensional accuracy, but can be limited in shape complexity.

- Machining: Achieves high precision and surface quality, but can be time-consuming and generate waste.

Quality Control and Inspection Techniques

Quality control is crucial in modern manufacturing to ensure product reliability and safety. Non-destructive testing (NDT) methods, such as ultrasonic testing and radiography, inspect materials and components without damaging them.

Statistical process control (SPC) monitors and analyzes production processes to identify and eliminate variations that could affect product quality.

Sustainability and Environmental Considerations

Manufacturing processes can have significant environmental impacts. Sustainable manufacturing practices aim to reduce waste, emissions, and energy consumption. These practices include recycling materials, using renewable energy sources, and implementing lean manufacturing techniques.

Emerging Trends and Future Directions

Modern manufacturing materials processes and systems continue to evolve. Additive manufacturing (3D printing) is gaining popularity, enabling the production of complex geometries and customized parts.

Advanced materials research focuses on developing materials with enhanced properties, such as self-healing materials, shape memory alloys, and bio-based composites. These advancements are expected to transform various industries and drive innovation in the years to come.

Answers to Common Questions: Fundamentals Of Modern Manufacturing Materials Processes And Systems 7th Edition

What is the significance of advanced materials in modern manufacturing?

Advanced materials offer exceptional properties such as strength, durability, and lightweight, enabling the production of innovative products and components with enhanced performance.

How does quality control ensure product excellence in manufacturing?

Quality control measures, such as non-destructive testing and statistical process control, monitor and maintain product quality throughout the manufacturing process, reducing defects and ensuring reliability.

What role does sustainability play in modern manufacturing?

Sustainable manufacturing practices prioritize reducing waste, minimizing emissions, and conserving resources, ensuring environmental responsibility and long-term viability.